Investing in a remote controlled lawn mower or industrial lawn mower is more than buying equipment—it’s about lowering costs, improving safety, and ensuring long-term efficiency for solar power stations. Photovoltaic plants require consistent vegetation management, and robotic mowing solutions provide a cost-effective way to achieve it.

Understanding Remote Controlled & Industrial Lawn Mowers

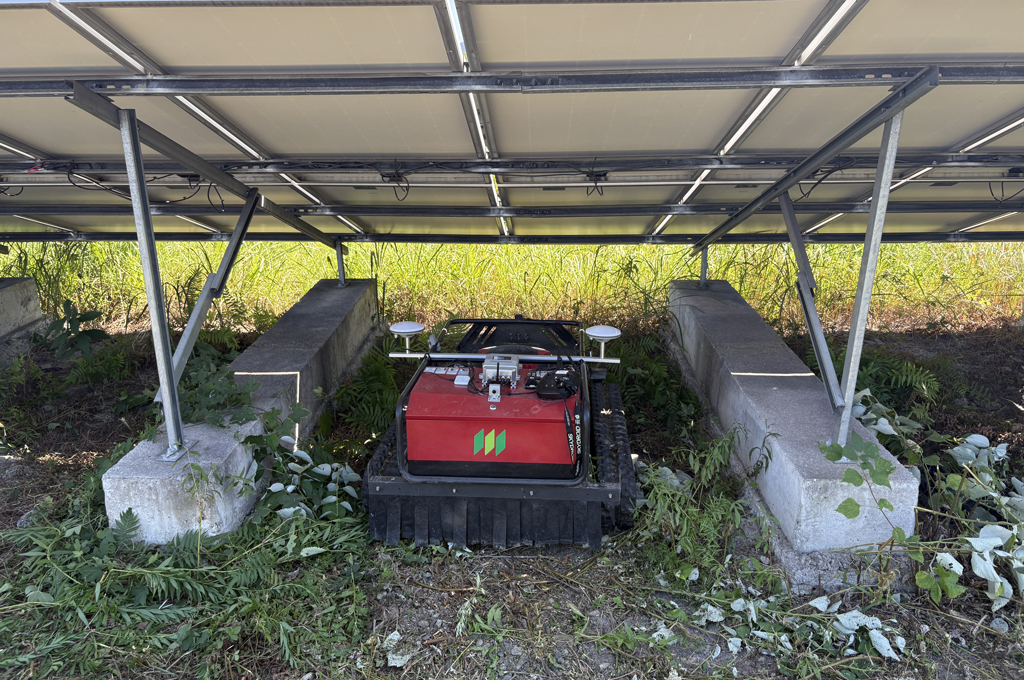

Traditional grass cutting in solar farms relies heavily on manual crews and ride-on mowers. These methods are labor-intensive, risky, and inefficient on slopes near photovoltaic panels. A remote controlled industrial mower solves these problems with crawler tracks, slope-climbing ability, and operator safety features.

Related Post: A Complete Guide to Remote-Controlled Mowers

How Mowers Reduce Costs in Solar Farms

- Lower Labor Costs: One operator can replace multiple crew members.

- Less Equipment Damage: Tracks minimize soil disturbance and reduce risks around panels.

- Reduced Downtime: Remote operation enables safe mowing even in challenging terrain.

Key Economic Advantages

- Higher Efficiency: Cut up to 4 acres/hour with industrial mowers.

- Long-Term ROI: Durable designs lower maintenance and repair costs.

- Safety Savings: Reduce workplace accidents and compliance costs.

- New Revenue Streams: Win projects in niche markets like solar farms, substations, and slopes.

Why Remote Controlled Lawn Mowers Fit Photovoltaic Power Stations

Solar power plants face unique vegetation challenges—grass shading panels reduces energy output, while slopes and ditches are dangerous for manual crews. A remote controlled lawn mower can:

- Safely mow slopes up to 45°–50°

- Reduce labor requirements by 70%

- Ensure consistent vegetation control and protect solar efficiency

How to Choose the Right Industrial Lawn Mower

When selecting a mower for a photovoltaic facility, consider slope capability, crawler track durability, remote range (200m+), and cutting efficiency. Investing in the right industrial lawn mower ensures long-term savings and maximum energy output.

Related Post: How to Choose the Best Lawn Mower for Hilly Terrain

Additional Insights for Solar Power Plants

For utility-scale solar farms, vegetation control is not only a matter of appearance but directly impacts energy production. Studies show that weeds and grass shading photovoltaic panels can reduce power generation efficiency by 5–15%. Traditional mowing methods are labor-intensive and often inefficient, while chemicals compromise environmental standards.

By deploying an industrial robotic mower or a remote controlled lawn mower, operators can overcome these challenges:

- Superior Terrain Adaptability: Robotic mowers can climb slopes of up to 45° and operate safely on uneven ground, desert areas, and embankments—terrain where traditional machines fail. Efficiency increases more than fivefold compared to manual crews.

- Cost Reduction: Automated mowing reduces labor expenses by up to 70–90% and lowers overall O&M costs by 30–35%, cutting per-square-meter costs to a fraction of manual work.

- Enhanced Safety: Crews no longer need to enter high-voltage areas or work under extreme heat. Accident rates fall to nearly zero, while insurance costs decrease by up to 50%.

- Power Generation Gains: Consistent vegetation control prevents panel shading, boosting energy output by 5–8% annually, which translates into significant financial returns.

FAQ: Remote Controlled Industrial Lawn Mowers in Solar Power Plants

Q: How does a remote controlled lawn mower improve solar farm efficiency?

A: By keeping grass trimmed, the mower prevents shading on panels and maximizes sunlight absorption for higher energy yield.

Q: Are industrial lawn mowers safe to use around photovoltaic panels?

A: Yes. Remote controlled mowers are designed with precision controls and crawler tracks, minimizing risks to panels and operators.

Q: Can one operator manage mowing for large solar fields?

A: Absolutely. A single worker can control the mower across wide areas or slopes, reducing crew size and payroll costs.

Q: What slopes can a remote controlled industrial mower handle?

A: Most models handle 45°–50° slopes safely, ideal for solar farms with uneven terrain and embankments.

Q: What is the ROI for solar power plants?

A: Operators save on labor, reduce accidents, and maintain consistent vegetation control, directly protecting solar power output and profitability.