The landscaping industry is undergoing a major transformation, and leading this shift is the industrial robotic lawn mower. Among them, the MC700 stands out as a purpose-built solution for solar farms, airports, industrial parks, and power plants, offering precision, efficiency, and safety at scale.

Unlike traditional automated mowers, the MC700 integrates GPS navigation, AI intelligence, remote control, and intelligent path planning, making it a complete industrial-grade solution for complex and large-scale landscapes.

GPS Precision: Centimeter-Level Accuracy for Industrial-Scale Operations

The MC700 industrial robotic lawn mower eliminates the need for buried boundary wires with its high-accuracy GPS navigation system. Equipped with Real-Time Kinematic (RTK) correction, it delivers centimeter-level positioning, ensuring precise mowing with minimal overlap or missed spots.

- Rapid deployment in large-scale sites such as solar panel arrays and airport runways.

- Flexible adaptation to frequently changing property layouts.

- Up to 80% lower installation costs compared to boundary-wire solutions.

AI Intelligence: Smarter Decisions for Safer Operations

Beyond GPS navigation, the MC700 leverages artificial intelligence to process real-time data from cameras, radar, and LiDAR sensors. This allows it to:

- Detect and avoid obstacles such as solar supports, equipment, or debris.

- Adjust speed and blade power according to slope and grass density.

- Learn from recurring mowing tasks, adapting to seasonal vegetation growth.

📌 In today’s industrial robotic lawn mowers, GPS and AI are tightly integrated to deliver reliable, wire-free navigation and smarter operations. With Real-Time Kinematic (RTK) correction, GPS achieves centimeter-level positioning, allowing the mower to stay precisely on planned routes without the need for buried boundary wires. At the same time, AI interprets data from multiple sensors—including cameras, radar, and LiDAR—to recognize the environment, adjust performance on slopes or dense grass, and safely maneuver around obstacles such as trees, equipment, or people. Together, these technologies transform robotic mowing into a highly efficient and adaptable solution for large-scale industrial and commercial sites.

Industrial-Grade Remote Control for Safety and Efficiency

The MC700 is equipped with an industrial-grade wireless remote-control system, ensuring precision and operator safety in hazardous environments:

- 200-meter control range keeps staff away from high-temperature or high-voltage areas.

- Multi-unit management: one operator can supervise multiple machines simultaneously.

- Flexible modes: including manual jogging, slope-adaptive slow start, and optimized turning.

- Real-time monitoring: instant updates on battery levels, machine status, and fault alerts.

This feature makes the MC700 particularly valuable for airports and power plants, where safety is critical.

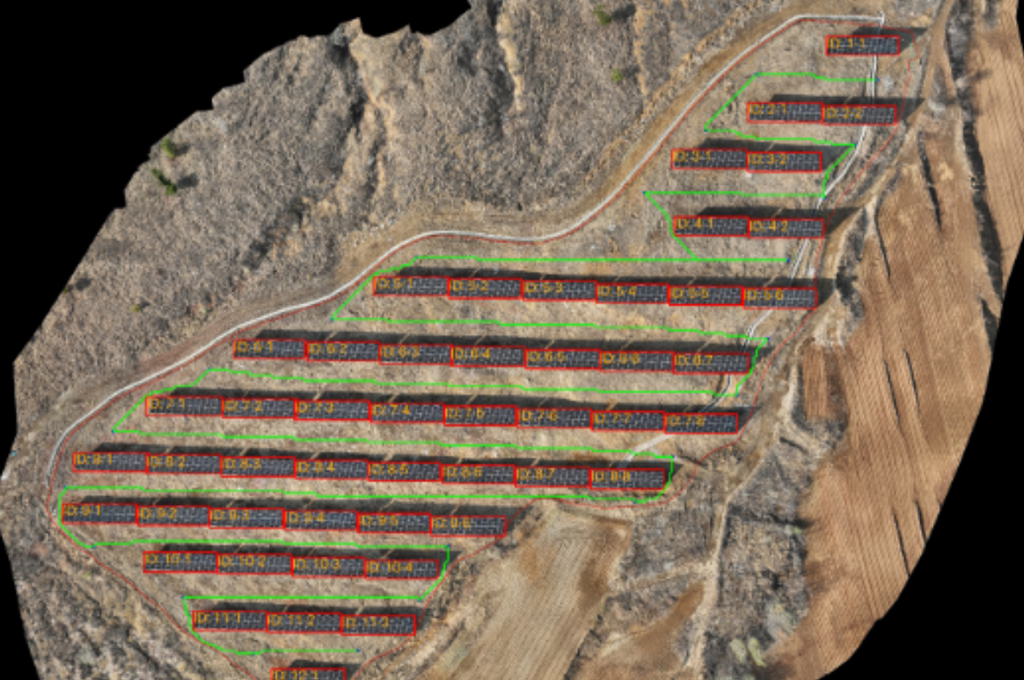

Intelligent Path Planning: Optimized Coverage for Complex Sites

With advanced path planning algorithms, the MC700 ensures consistent mowing performance across large and complex industrial properties:

- Point-to-line planning for solar panel arrays, airport runways, and utility sites.

- Smart obstacle avoidance reduces downtime and manual intervention.

- Route memory supports recurring, automated mowing schedules.

- Slope adaptability ensures reliable performance in hilly or uneven solar farms.

Core Application Scenarios

- Solar Farms: Prevents vegetation from shading panels, ensuring stable energy output.

- Airports: Maintains turf safely around runways and sensitive infrastructure.

- Industrial Parks & Power Plants: Reduces labor dependency with automated large-scale mowing.

Sustainability and ROI

The MC700 delivers measurable cost savings and environmental benefits:

- Zero emissions with electric-powered operation.

- Low noise levels, suitable for industrial zones near communities.

- Autonomous charging for continuous uptime.

- 30–50% annual maintenance cost reduction compared to manual mowing.

The Future of Industrial Robotic Lawn Mowing

As AI and sensor technologies continue to advance, the MC700 will evolve further with:

- Cloud-based fleet management for large-scale operations.

- AI-driven predictive maintenance to reduce downtime.

- Integration with smart energy and airport infrastructure.

The MC700 industrial robotic lawn mower is not just a machine—it is a complete landscaping solution built for the world’s most demanding industrial environments. By combining GPS precision and AI intelligence, it sets the standard for safe, efficient, and sustainable large-scale vegetation management.

👉 Looking to optimize vegetation management for your solar farm, airport, or industrial site?

📩 [Contact us today] to discover how the MC700 can reduce costs, improve efficiency, and support your sustainability goals.